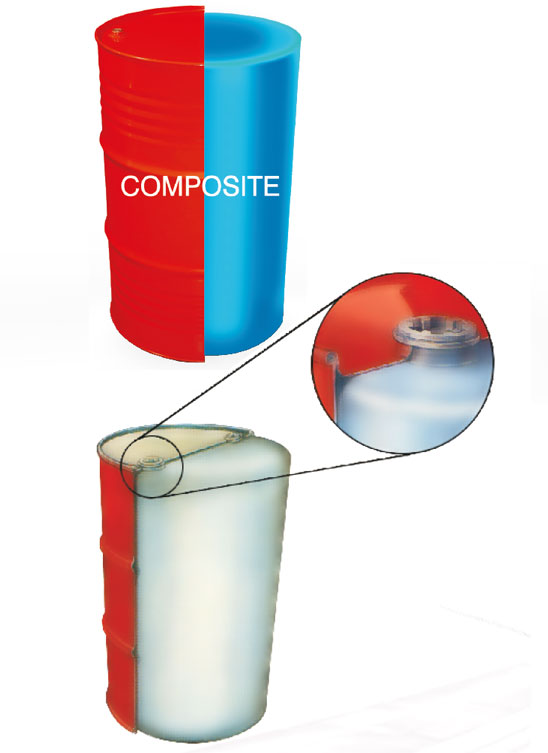

Composite Drums (Steel outside, Plastic inside)

Mainly used to fill products not compatible with steel But need it for strength.

Features and Benefits

- Reduced transportation costs due to its conical shape allowing them to be nested inside each other

- Reduced storage space

- Perfect palatization and containerization

- Drum bottoms are double seamed

- Resistance seam welded side seam.

- Single top bead to retain dimensional integrity of the diameter.

- Manufactured from Prime C.R.C.A steel.

- Top end assembled with flat/circular or semi circular, solid or hollow cross sectional gaskets.

- Manufactured to meet shipping specifications (Indian & international)

- Automated cleansing process used to clean internal and external surface.

Options

- Thicknesses available between 0.7mm to 1.2mm

- Externally painted to colours of your choice using Pure Stoving, Epoxy or P.0 paints

- 210 litre capacity is available

- Internally plain /phosphated/ painted/ lacquered are offered

- Seaming compound options include various types of latex and epoxy based sealants depending on product compatibility

- Locking rings with lever arrangements are offered in various thicknesses and finishes

- Packing material options for transport protection – Corrugated Paper/Stretch Wrap/Bubble Wrap

- Electro-galvanised and stainless steel 304/316 options are also available.

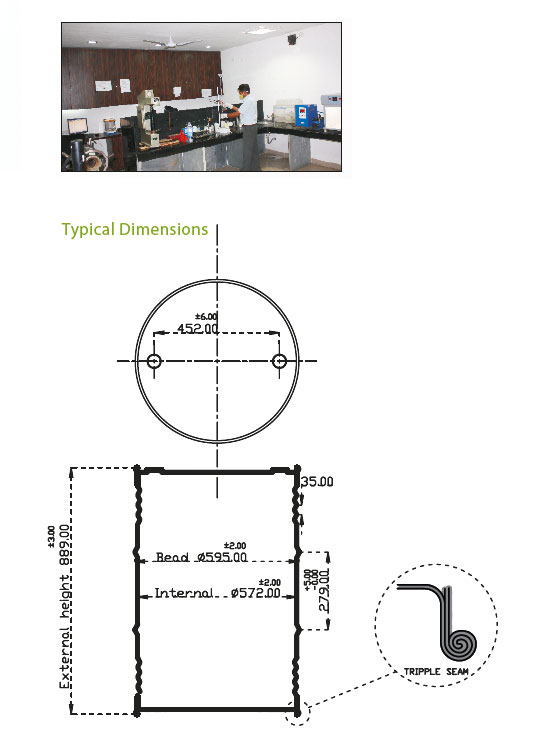

TYPICAL DIMENSIONS OF COMPOSITE TIGHT HEAD DRUM.

* These are only indicative dimensions and may change.